Recently I put something together to illustrate this – This is an off-the-shelf audio preamp-amplifier pair that’s immersed in ElectroCool EC-110 Dielectric Coolant. The preamp is analog, using vacuum tubes. The amplifier is solid state. It’s all being cooled by immersion in ElectroCool, and is working perfectly.

Obviously this small preamp/amplifier isn’t producing much heat, and would need a pump and cooling loop if it were. But moving heat away from hot components is the easy part of immersion cooling. The difficult part is making a coolant fluid that’s compatible with a huge variety of materials and components and will have a service life of 10 years or more. ElectroCool does all that. There’s no fluorine or other dangerous halogens. Electrocool is not aggressive to sensitive electronics, it’s biodegradable, nontoxic and even classified as Food Grade.

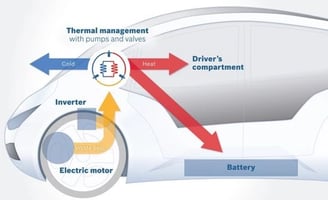

Our dielectric coolants are used in thermal management of medical devices, automobile chargers, RF and microwave transmitters, robotic motor controllers and a thousand other applications. Cooling electrical assemblies by immersion eliminates vibration, temperature swings, moisture, acids, dirt, and other contaminants. The coolants don’t boil or evaporate; they circulate quietly and cleanly, moving heat from where it’s generated to where it can be released or reused.

This demo illustrates how ElectroCool can be used with “Commercial Off-The-Shelf” (COTS) electrical and electronic equipment. The amplifier was taken straight out of its box and immersed, with no circuit board coating, protection or other preparation needed. ElectroCool Coolants can help you with your thermal management challenges, too. Contact Engineered Fluids and we’ll show you how.