Electric Vehicles require several different types of fluid products than what we're used to; they...

Spot-Market Coolants?

“Let’s go to the electronics store and we’ll use whatever memory they have on sale today” said no manufacturing engineer, ever. Can you imagine the variation in quality and reliability this would introduce into their products? But, with realizing it, many engineers do this very thing with their choice of liquid coolants.

Some try a “do it yourself” approach by buying mineral oils or a synthetic base from a lubricant distributor. Some buy “ours is the same but it’s cheaper!” oil from a tank supplier. Either way, there’s a huge difference in quality and confidence you get when using a purpose-made, manufactured and tested dielectric coolant.

When buying commodity base oils that are not designed to be used as finished dielectric coolants, customers quickly find out how little control there is in the oil’s characteristics. There can be huge swings in quality and in composition, from batch to batch and drum to drum. Critical characteristics, such as dielectric strength, moisture content, acid value, and sludge content aren’t controlled, tested or reported. Buyers don’t know what they’re getting – it worked once, maybe it will work again. Maybe.

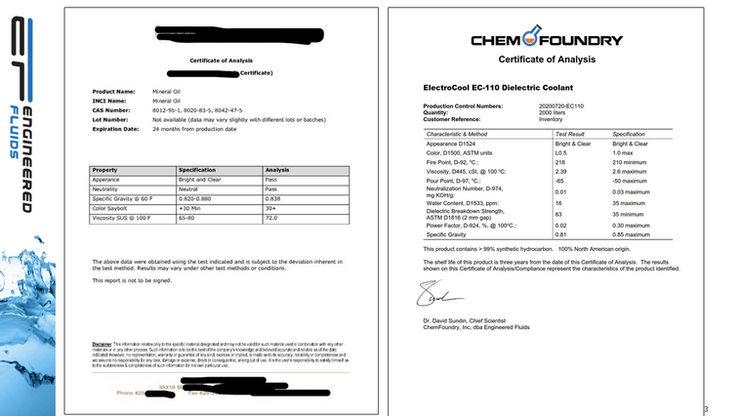

Here’s a comparison of two Certificates of Analysis – one for mineral oil and one for ElectroCool EC-110 from Engineered Fluids.

When you buy mineral oil, you get a Certificate that lists Appearance, Neutrality, Color and Viscosity (note that the viscosity specification is wide enough to drive a truck through). Want to know whether a material or specific server or BitCoin miner is compatible with the oil? Good luck; there’s no guidance on that from the oil manufacturer.

When you buy Engineered Fluids’ purpose-built dielectric coolants, you get a Certificate that shows the full set of physical, chemical and electrical characteristics. There’s a batch number for traceability. You have a complete Material Compatibility Guide available to you on the web (https://www.engineeredfluids.com/material-compatibility). And, you can call us and speak directly with application engineers and scientists.

Our products are made to an exact set of standards in an ISO-9001 qualified facility and Quality System. They’re tested at different stages during and after the manufacturing process, and guaranteed to meet all demanding requirements.

You wouldn’t get your servers, power supplies or other components on the Spot Market at your local electronics store. Don’t choose your coolant fluid the same way. Choose security and confidence – choose Engineered Fluids’ line of safe, tested dielectric coolants.